PMAV: Personal Micro Air Vehicle.

Build it from scratch in less than an hour.

Fly it in your backyard. No prior experience required.

Takeoff Vertically.

|

|

|

|

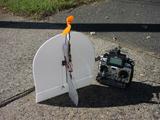

| The PMAV: a new concept in radio-controlled electric aircrafts |

- The PMAV is very easy to build. It can be built from scratch by anyone in less than an hour (see plan and building instructions below).

- It is very easy to fly, even for total beginners.

- It is very sturdy, and practically unbreakable.

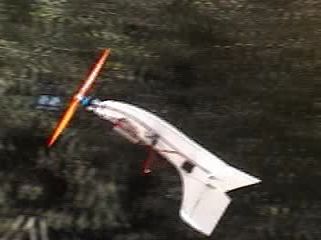

- It is highly maneuverable and can even take off vertically. See pictures and videos below.

|

|

|

|

Specifications

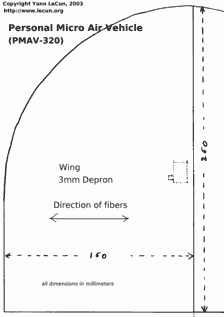

- wingspan: 320mm, length: 360mm

- mass: less than 100 grams, including battery (2 cell Kokam LiPo, 340mAh)

- motor: GWS "Light Power System" LPS CN12-RLC 7.2V B (5:1 gear ratio)

- prop: GWS orange props: 6050 (beginners), 8043 (experienced pilots), or 9047 (experts, allows vertical takeoff).

- radio: GWS receiver with 2 GWS Pico servos.

- battery: 2 cell Kokam Lithium-Polymer, 340mAh

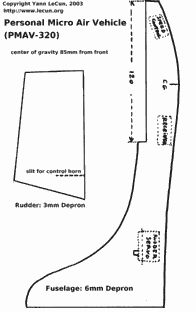

- materials: wing: 3mm Depron; fuselage: 6mm Depron; motor mount: 6mm diameter carbon tube

- design: Yann LeCun, October 2003

What makes the PMAV so special

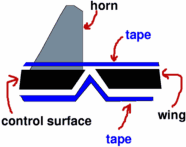

- The PMAV control surfaces consist of an elevator and a rudder which is mounted on a downward-pointing tail fin (placed below the wing). This configuration allows the PMAV to bank automatically while turning, without requiring ailerons.

- Unlike with traditional aileron-controlled airplanes, it is practically impossible to flip the PMAV upside down. This makes the PMAV very easy to fly by children and beginner pilots.

- Its larger-than-one thrust to weight ratio and high maneuverability make it fun for expert pilots.

- The low aspect ratio wing is compact and sturdy. It also allows ultra-low-speed flight at very high angles of attack.

- The larger-than-one thrust to weight ratio allows vertical takeoffs and high-speed horizontal flights.

- The construction is fast, simple, and requires no glue (everything is held together with tape!).

- You can take the PMAV anywhere with you (on plane trips...). The wing and fuselage are held together with double-sided mounting tape and can easily be disassembled and reassembled.

|

|

|

|

|

|

|

|

| Building the PMAV |

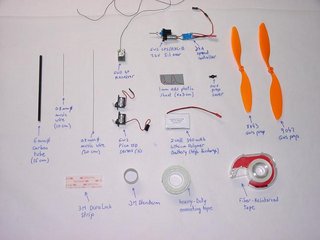

List of Material

Here is a list of what you need to build the PMAV-320. A picture of all the items is shown here. Click on the links for high resolution versions of the picture in DjVu or JPEG.

|

| DjVu, High-Res (1600x1200, 116KB) |

| JPEG, High-Res (1600x1200, 286KB) |

| JPEG, Medium-Res (800x600 41KB) |

- 3mm Depron sheet: 320x320mm

- 6mm Depron sheet: 300x200mm

- Carbon tube, diameter: 6mm, length: 150mm.

- music wire: diameter 0.8mm (or similar), length: 300mm

- small sheet of ABS or Styrene: thickness: 1mm (or similar), dimensions: 60x30mm

Tape and Supplies

- to hold the battery: a strip of 3M DuraLock (a Velcro-like thingy made of hard plastic). This can be found at any hardware store. If you can't find DuraLock, use sticky Velcro pads.

- to make the hinges: a roll of 3M Blenderm, or any other surgical-type extensible tape that sticks well on Depron. Blenderm can be obtained from Air Dynamics.

- to hold the motor mount to the fuselage: a roll of fiber-reinforced tape (available from any hardware store).

- to hold the wing to the fuselage: a roll of double-sided mounting tape (available from any hardware store).

- to hold the horns to the control surfaces: a roll of thin double-sided tape, or some foam-friendly (odorless) CA glue, or some 5-minute epoxy.

- to hold the prop to the motor: a few small rubber bands

Radio/Motor. All of this can be obtained from Balsa Products.

- Receiver, e.g. GWS 4P 4-channel receiver.

- Two submicro servos, e.g. GWS Pico, Cirrus 4.9, Cirrus 4.4...

- Motor: GWS "Light Power System" 7.2V LPS-RXC B (5:1 gear ratio)

- 4 Amp motor speed controler, e.g. GWS controler, or a Castle Creation Pixie 7P.

- GWS prop saver

- GWS orange propellers: 6050 (beginner pilot), 8043 (intermediate pilot), and 9047 (expert pilot). By a few, because you might break them.

- Lithium-Polymer Battery pack: 2 cells, 340mAh from Kokam. Other brands of LiPo batteries may be used as long as they can put out 5 Amps (e.g. Taisun 750mAh, E-TEC, I-RATE....).

- Charger for Lithium-Polymer batteries.

- Transmitter.

Printing the Plan

|

The plan consist of two sheets that can be printed on regular-sized

paper (US-Letter size or A4). Each sheet is provided in two format:

PNG and DjVu. I very strongly recommend that you use the DjVu version,

because the DjVu viewer allows you to print the plan at real size.

Downloading and installing the DjVu viewer takes only a minute. To print the DjVu plan, bring up the DjVu version of the plan, and click on the printer icon in the DjVu window (do not select your browser's "print" menu). In the DjVu printing options, select "one-to-one" as the printing scale. |

|

Detailed Building Instructions

The center of gravity should be approximately 85mm from the front of the wing. If necessary, the position of the CG can be adjusted by modifying the position of the battery.

That's it. Your PMAV is ready to fly.

| Flying the PMAV |

With the 6050 prop, the PMAV is very gentle and can be flown by just about anyone. The plane is so light that even a full speed crash in a hard surface will not cause any damage (assuming the "prop saver" option was implemented).

With the 8043 prop, the flight is a lot snappier. It becomes possible to fly around at very low speed with a "nose up" attitude (high angle of attack).

With the 9047 prop, it is possible to take off vertically. Just put the PMAV on the ground, and apply full power. The PMAV will take off, and rotate around a vertical axis (1/2 turn to a full turn). The nose will then come down by itself.

| Pictures and Videos |

These videos demonstrate the extreme maneuverability, huge speed range, and sturdiness of the PMAV. Most videos were shot in the street and front yard of a typical suburban home with lots of obstacles around (trees, cars, telephone poles, cables, intrigued neighbors,...).

- mav01-handlaunch01.mpg [3150KB]: a hand launch and a normal flight

- mav01-landing01.mpg [2455KB]: a soft landing

- mav01-vtakeoff01.mpg [2678KB]: vertical takeoff

- mav01-vtakeoff02.mpg [4233KB]: vertical takeoff

- mav01-vtakeoff03.mpg [927KB]: vertical takeoff

- mav01-vtol01.mpg [2563KB]: vertical takeoff and attempt at vertical landing

- mav01-vtol02.mpg [4291KB]: vertical takeoff and attempt at vertical landing

- mav01-crashintree01.mpg [1280KB]: a crash into a tree

- mav01-deadleaf01.mpg [6706KB]: diverse flight conditions, and a crash in a tree branch

- mav01-fast01.mpg [7690KB]: high-speed flight

- mav01-flyingaround01.mpg [9121KB]: just flying around

- mav01-fullspeedcrash01.mpg [7913KB]: high-speed crash into a tree branch

- mav01-longflight01.mpg [15537KB]: a long flight sequence

- mav01-lowspeed01.mpg [4837KB]: low-speed flying hanging by the prop at a high angle of attack

- mav01-rasemotte01.mpg [8136KB]: flying a couple inches from the ground

- mav01-slow01.mpg [4456KB]: low-speed flying

- mav01-slow02.mpg [11693KB]: low-speed flying

- mav01-ronan01.mpg [5375KB]: a 14 year old flying the plane at a park.

186

186